LMS Machinery Company

Guangzhou LMS Machinery Co., Ltd, established in 2010, is an expert partner for slitting lines and cut to length line machines. Our core expertise lies in the research and production of metal strip slitting lines, metal coil cut-to-length lines, rotary-shear cut-to-length lines, swing shear lines, flying shear lines, as well as the combination of slitting and cut-to-length lines.

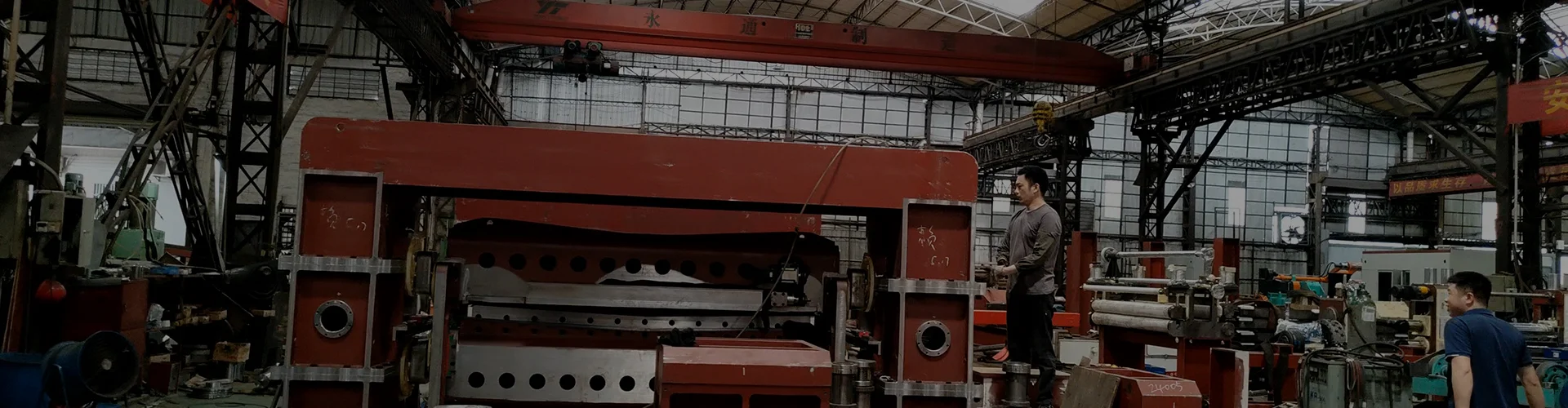

LMS workshop occupies a 30,000 sqm and uses high-precision CNC equipment to produce high-quality machines compliant with ISO 9001 standards. Over 20 years experiences, our team of professionals has jointly developed slitting and cut-to-length lines with exceptional performance and durability.

LMS Machinery's products are recognized globally and are used in multiple industries including steel trading and service centers, automotive, home appliances, construction, steel pipe and tube profiling, and direct end-user applications.

LMS Machinery provides advanced technology, top-quality machines, and exceptional service guarantees.These ensure all customers benefit from high performance, reliability, and ease of operation for modern steel processing equipments.

Established in 2010

LMS workshop in

Annual output

Continents

SLitting Line , Cut-To-Length Line Manufacturer

LMS Machinery occupies a 30,000 sqm workshop and uses high-precision CNC equipment to produce high-quality machines compliant with ISO 9001 standards, with annual output of 80 units.

CNC Workshop is equipped with over 20 sets of CNC machine tools, including 7 sets of gantry milling and boring machines for high-speed CNC machining of machine frames and rolls.

Assembly Workshop, thanks to the expertise of skilled mechanical engineers team, has the capability to simultaneously assemble 4 lines of slitting line and cut-to-length line equipment.

Product area can accommodate up to 6 production lines for automation control wiring assembly and testing.

Machine Delivery will be in PVC film packed and fixed in cargo containers, and important spare parts will be packed in wooden cases.

LMS Service

Detailed project consultation

In-house design office mechanical and electrical design

Machine in-house manufacturing and assembly

External assembly and commissioning with LMS engineers

Successful project completion

1 year warranty

Lifetime Online support

Spare parts manufacturing