High Automation New Generation

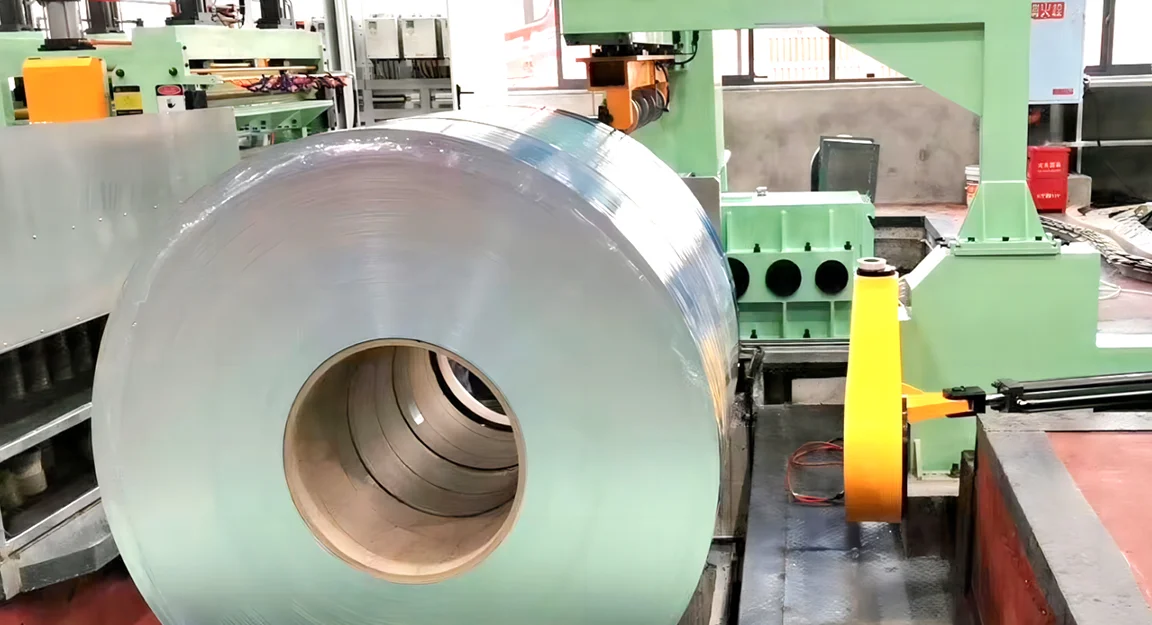

LMS designs and manufactures slitting lines for Carbon Steel, Stainless Steel, High tensile steel, Electric steel, ferrous strips as well as non-ferrous strips. Our focus is on producing innovative and advanced machinery that meets the demands of the modern metal industry.

The capacity of LMS Slitting lines range from 300mm to 2200mm (width) and 0.10mm to 10.0mm (thickness) in strips and coil weights up to 40 MT, and speeds up to 230 m/min.

Line Specification

COIL WEIGHT

Up to 40MT

Up to 88,184lb

STRIP WIDTH

Up to 2200mm

Up to 86.6”

MATERIAL THICKNESS

0.1 to 10mm

0.0039” to 0.39”

SPEED

over 200m/min

over 656f/m

Equipment Features:

Our focus is on producing innovative and advanced machinery that meets the demands of the modern metal industry. LMS Machinery is dedicated to delivering the high automation solutions for our clients' metal slitting needs.

High productivity and automation is key feature of advanced slitting line, from uncoil centering to threading and recoiling, to minimize human intervention, reducing the risk of errors and increasing productivity.

High quality metal slit coils are created using a robust slitter head that minimizes arbor bending and features a "0" axial gap and advanced tooling locking system. The advanced braking system provides uniform tension for each slitting strip during recoiling, ensuring that the strips are wound tightly and have straight edges.

More innovative solution could involve the integration of additional devices such as various tensioning systems, PVC/ paper filming equipment, belt wrappers, turnstiles, and more to cater to a diverse range of slitting requirements.

Technical Characteristics:

| Machine Range | HIGH PRECISION | LIGHT GAUGE | MEDIUM GAUGE |

| Thickness | 0.1-0.6mm | 0.3-4mm | 1.5-10.0mm |

| Width max | 1500mm | 1800mm | 2100mm |

| Coil Weight max | 20MT | 30MT | 40MT |

| Work speed max | 230mpm | 230mpm | 120mpm |

Industry Applications

Aluminium

Aluminium

Stainless steel

Stainless steel

Pre-painting steel

Pre-painting steel

Copper and brass

Copper and brass