Aluminium industry company user

Feb 13,2025

Aluminium industry company user focus on aluminium coil processing service, which product involved from light gauge thickness 0.2mm to heavy gauge thickness 12mm, coil width covers from 15mm to 2300mm, therefore needs 3 sets of coil cutting line to meet their market as following:

1 .Rotary shear cut to length line (dual stacking system)

- Process material: aluminium coil:

- Raw coil thickness :0.2-3.0mm

- Raw coil width: 200-1350mm

- Product sheet length: 300-4000mm

- Raw coil thickness :0.2-3.0mm

- Machine components:

- Auto centering hydraulic decoiler with auto upload coil cart to unwinding the metal coil.

- 6-Hi leveling machine for high quality plate flatness without roll marks.

- PVC laminating application for pvc filming or paper lining.

- High automation with precision feeding system controlled by PLC.

- Famous rotary shear system and motor driving eccentric rotation of cutting blades.

- Double stacking systems for enhancing production.

- Auto centering hydraulic decoiler with auto upload coil cart to unwinding the metal coil.

- Machine advantage:

- High speed cutting up to 90m/min for short metal sheet cutting.

- Non-stop cutting to protect metal strip surface.

- High speed cutting up to 90m/min for short metal sheet cutting.

2. Flying shear cut to length line (dual leveler, edge slitter)

- Process material: aluminium coil:

- Raw coil thickness :1.0-8.0mm

- Raw coil width: 200-2000mm

- Product sheet length: 1000-6000mm

- Raw coil thickness :1.0-8.0mm

- Machine components:

- Auto centering hydraulic decoiler with auto upload coil cart to unwinding the metal coil.

- Hi leveling machine to be first leveler after uncoiler machine.

- Looping pit for metal strip buffering for high speed running.

- Edge trimmer and scrap rewinder for removing crack edge of metal coil.

- 4-Hi leveler to be another leveler after edge trimming.

- PVC laminating application for pvc filming or paper lining.

- Flying shearing system with cutting head for continuously move along the metal strip.

- Auto stacker for drop metal plate in neat shape on pallet ready to pack.

- Auto centering hydraulic decoiler with auto upload coil cart to unwinding the metal coil.

- Machine advantage:

- High speed cutting up to 50m/min for long metal sheet cutting.

- Non-stop cutting to protect metal strip surface.

- High speed cutting up to 50m/min for long metal sheet cutting.

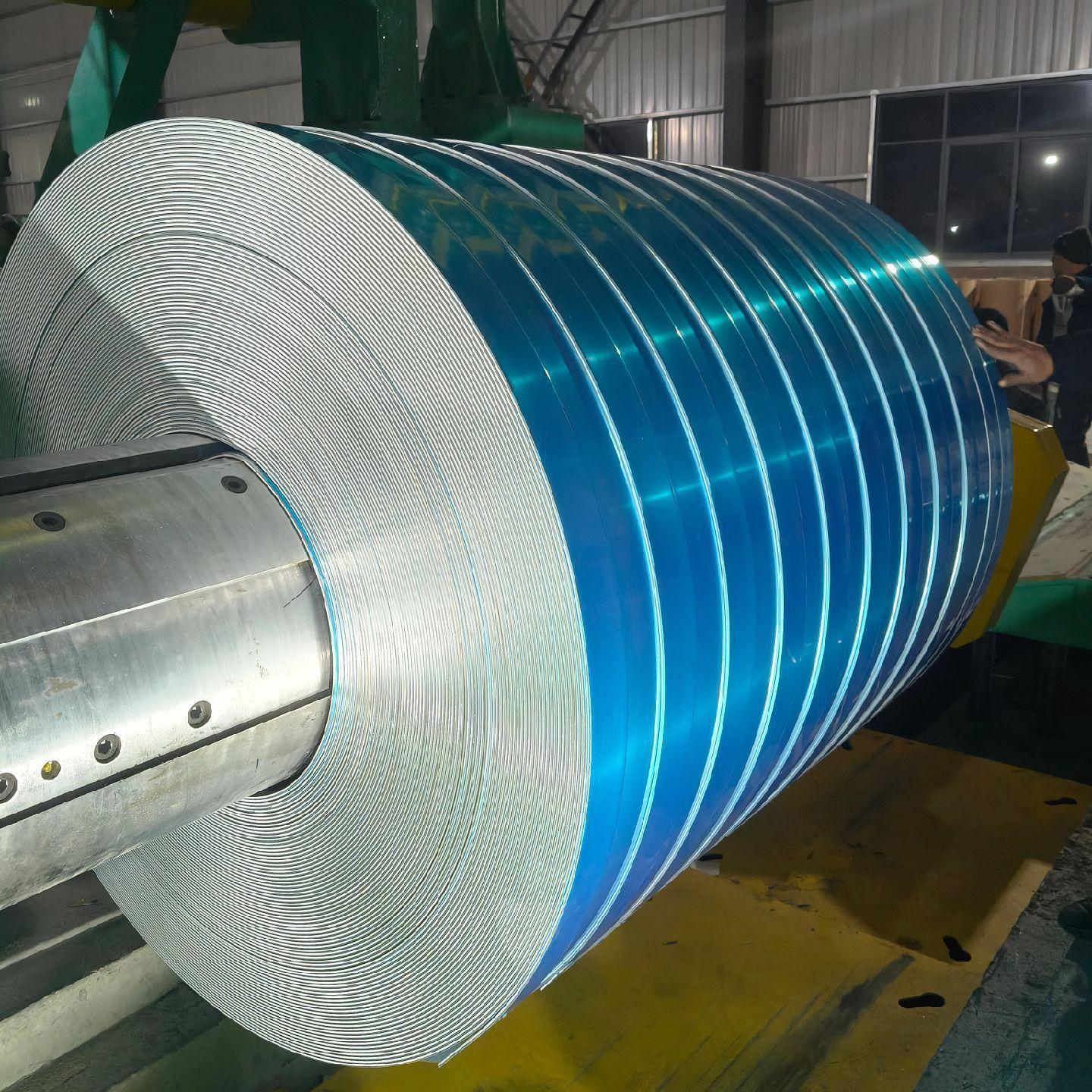

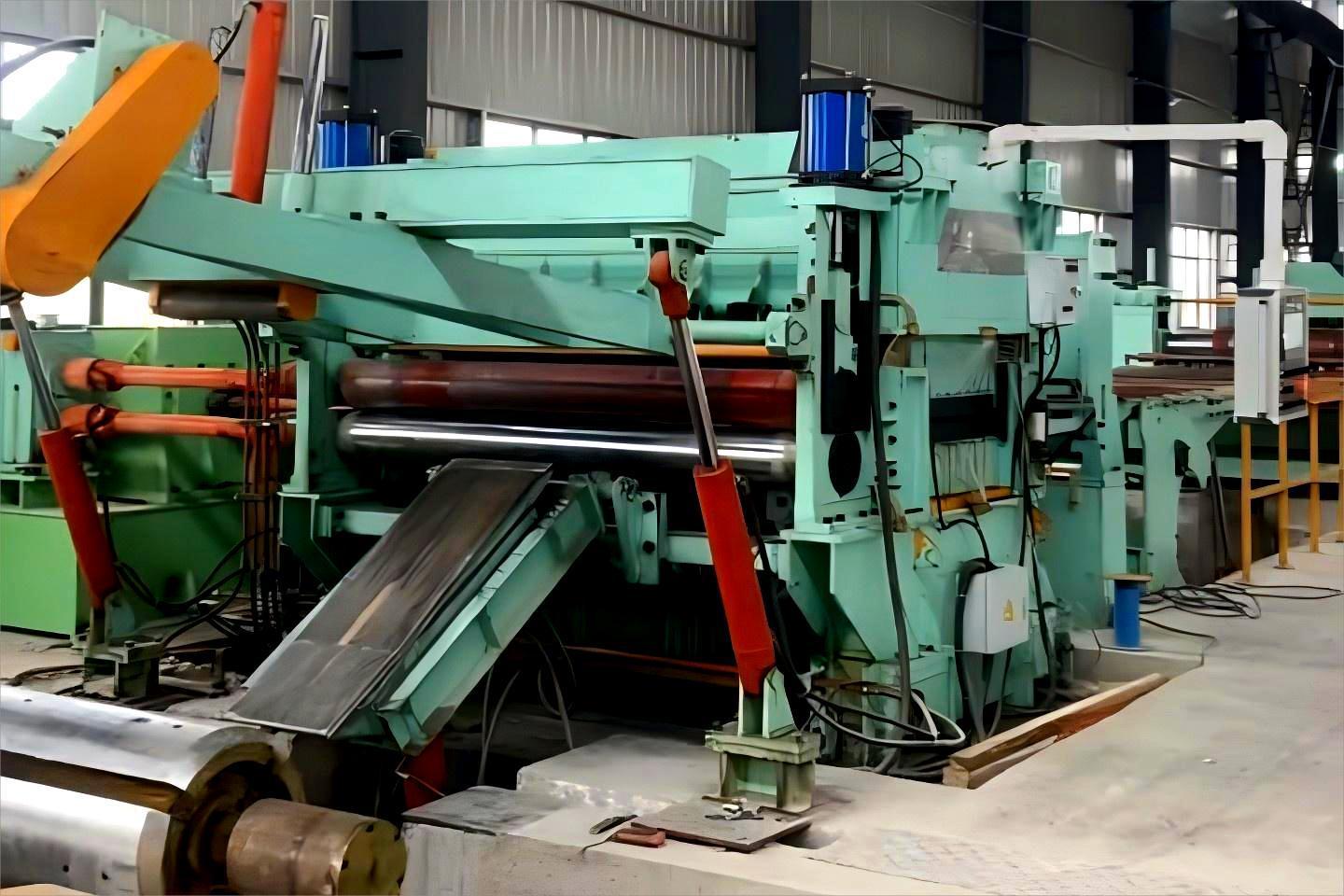

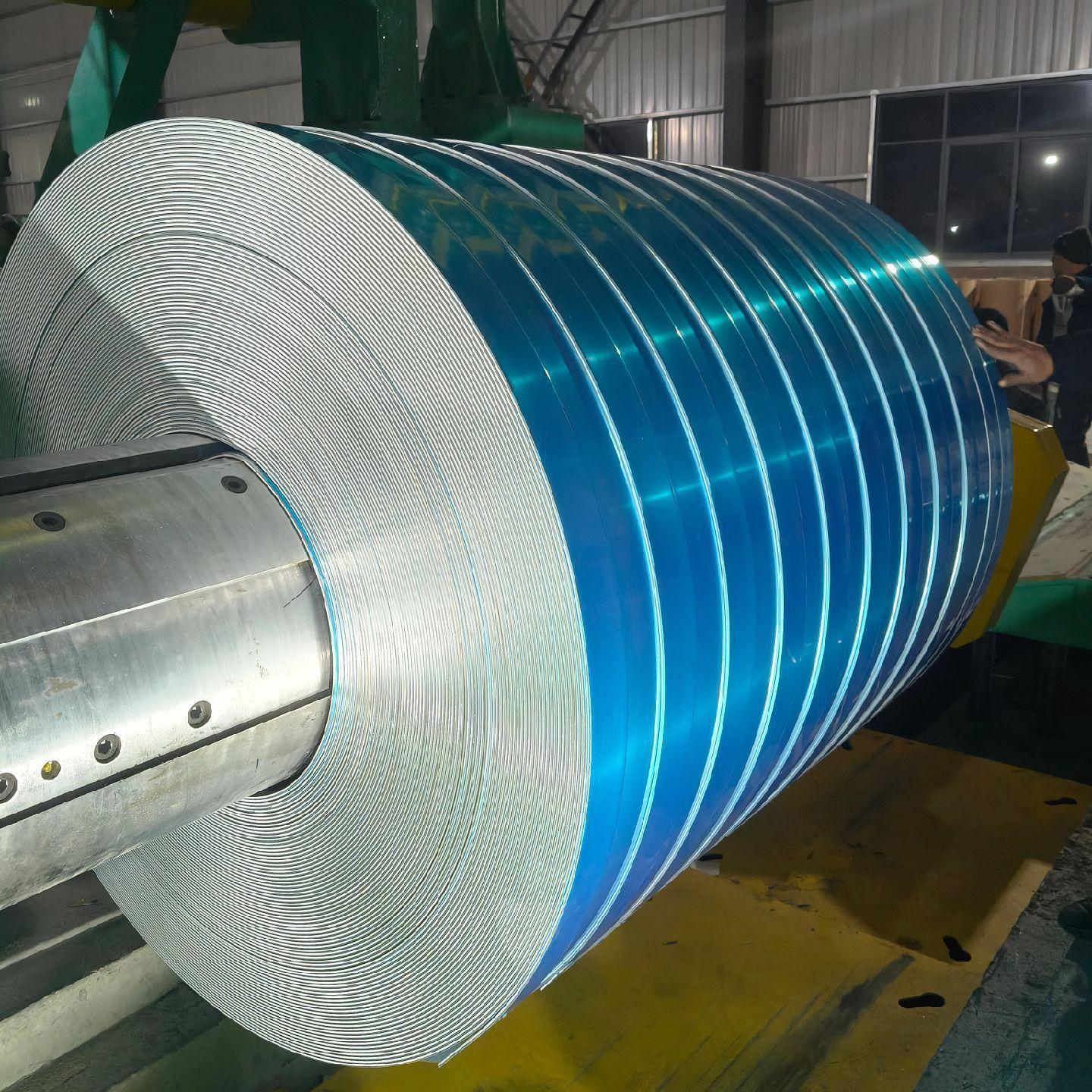

3. Slitting line (dual slitter, dual recoiler)

- Process material: aluminium coil

- Raw coil thickness :0.2-10.0 mm

- Raw coil width: 2300 mm

- Slitting strip width: 15-2300 mm when 0.2-4.0 mm thick, 32-2300 mm when 4.01-10 mm thick

- Slitting strip inner diameter: 305 mm/ 405 mm/508 mm/610 mm

- Slitting strip outer diameter: max 2000 mm

- Raw coil thickness :0.2-10.0 mm

- Machine components:

- Paper rewinder for paper of PVC film on raw material coil.

- Auto centering hydraulic decoiler unwinds the metal coil in constant tension.

- roll leveling machine and hydraulic shearer to handle unevenness of metal strip.

- 2 Looping pits before and after slitting machine for metal strip buffering .

- PVC laminating application for pvc filming or paper lining.

- Double slitter with gap digital indicator for knife shaft adjustment.

- Pre-dividing, Pad tension system , 3-roll tension and hydraulic post-shearing .

- Recoiler machine with clamping claw and auto rising separating arm.

- One rewinding machine for aluminium coil, another rewinder for larger slitting strip coil.

- Paper rewinder for paper of PVC film on raw material coil.

- Machine advantage:

- High productivity speed up to 150 m/min for heavy gauge metal coil slitting.

- Auto metal strip threading though the slitting line.

- High productivity speed up to 150 m/min for heavy gauge metal coil slitting.

For more slitting line and cut to length line, contact info@slittinglinelms.com. LMS slitting line will design and manufacture the coil cutting line according to your coil specification, production requirements and factory layout.

Articoli recenti